When evaluating completion damage, one of the most versatile and commonly deployed downhole logging tools is the Multifinger Caliper (MFC). The MFC has been the backbone of tubing and casing integrity assessment for decades, allowing for quick and precise evaluation of the completion’s condition with levels of precision and accuracy in the thousands of an inch. Nonetheless, a huge number of MFC surveys do not reflect the true nature of the downhole conditions they were meant to detail, with overestimations of recorded penetrations potentially causing millions of dollars in unnecessary workover expenditures.

MFC data and, more specifically MFC data processing, has often been seen as less complex, less challenging than it’s more “fashionable” counterparts such as multi-string Eddy current or ultrasound-based probes. And for decades, albeit accounting for the vast majority of well integrity assessment surveys, no renewed focus has been given to MFC data analysis. Legacy software still employ the same methods as they did over 15 years ago and ignore challenges and errors that have remained unaddressed for much longer than they should have.

One such challenge is the calculation of wall loss – percentage penetration of defects, corrosion, erosion, etc – in ovalised tubing or casing.

Almost all completion tubulars are indeed ovalised to a certain degree, their manufacturing process being such that perfectly round joints are not the target outcome. This small degree of ovalisation is not an issue in most cases, with tolerances with regards to wall thickness, internal and external diameter constituting the main factors being controlled for.

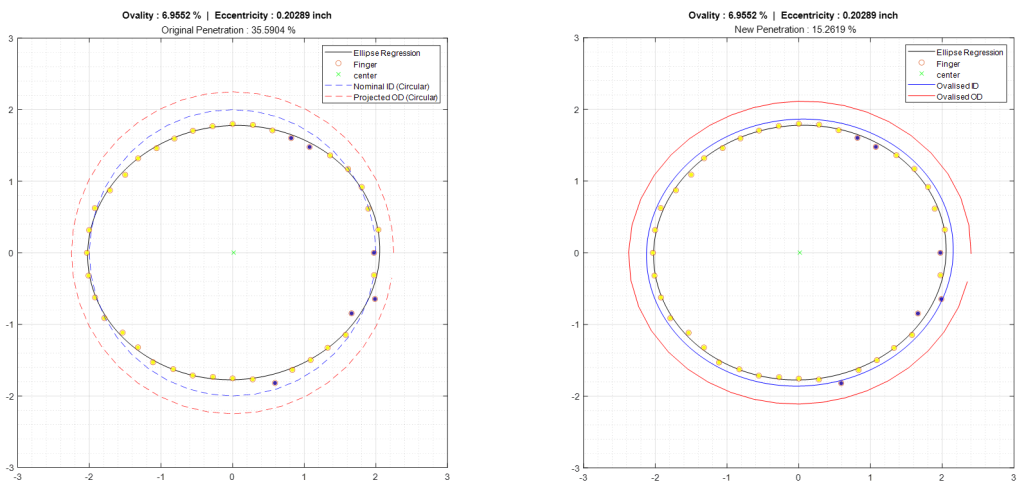

The problem arises when assessing the internal diameter (ID), and thus estimating the remaining wall-thickness (WT), of in-situ joints using the MFC as every commercially available legacy software used to accomplish this goal is unable to take into account the background ovality of the joints being assessed. One way of intuitively understanding this problem is to imagine an ovalised cross-section: one axis being longer (semi-major) and the perpendicular axis being shorter (semi-minor) – if a penetration is recorded along the semi-minor it will be underestimated, meanwhile, one recorded along the semi-major will be overestimated. This is the result of assuming that the nominal internal diameter and outer diameter are not affected by ovalisation.

The difference between the true penetration value and the distorted results caused by failing to take tubular ovalisation into account can be drastic, with our research having identified cases where penetrations were reported to be over 35%, 20% larger than in reality. In one particular case, the overestimation had led to plans being made for a costly intervention, which was only avoided incidentally as we were able to show the mechanisms described here as being behind the increased numbers.

But why is taking ovalisation into account so difficult? The challenge stems from the cornerstone of MFC data processing: data centralisation. Centralisation is perhaps the most crucial step in achieving coherent and accurate results when it comes to MFC data analysis, with the imperative to identify the correct parameters and apply the best methods in order to correct the effects of tool eccentricity while logging.

Every MFC survey data has, in its inception, a degree of eccentricity. This is an unavoidable physical phenomenon as, no matter how strong the mechanical centralisation force applied, some deviation between the toolstring and the completion centreline will occur in deviated sections of the well. The conventional approach to calculate this eccentric (and subsequently correct for it) is to apply a regression technique to the acquired data. This data-fitting is usually done by simpler, less computationally intensive methods, such as sinusoidal fitting while assuming the tubular is perfectly circular. Some software does allow for more precise fitting, perhaps using multiple regressions and the assumption of an elliptical path, nonetheless, none (besides Clarity that is) has developed and demonstrated robust methods to avoid the biggest pitfall of data centralisation: outliers.

Outliers are often the actual reason a MFC survey is taking place. These are the values which were recorded when the tool has observed sections of the completion which are *not* aligned with the expected circumferential profile of a clean, debris and defect free cross-section. The tricky part is how to identify these outliers and exclude them from the regression deployed to calculate eccentricity. Enter PRISM, our in-house AI system which allows every single cross-section of acquired data to be independently analysed and assessed. This means regression is applied to every depth-frame of the dataset with individually optimised parameters, something that is far beyond what would be possible if parameters were to be selected manually by an analyst.

By correctly identifying outliers (features, damage, deposition, etc) while both acknowledging that joints are never perfectly round and deploying new and innovative techniques to achieve eccentricity correction, MFC data can be processed and analysed with unprecedented levels of accuracy where it matters the most. The difference between pulling a completion or not can be only a few clicks away.

Can we help? Talk to us about your data analysis and interpretation requirements.

Find out what’s been making the headlines from across the world of ANSA.

ANSA Customer Support

+44 (0) 1224 336624 sales@ansa-data.com

Aberdeen Data Hub

Viking House, 1 Claymore Avenue, Aberdeen Energy Park AB23 8GW. UK

Houston Data Hub

Suite 330 9940 W. Sam Houston Parkway S. Houston, Texas 77099. USA