Our ANSA data analytics expertise played a vital role in a rig work-over that turned from routine to complicated. Fast turnaround analysis allowed the operator to complete the operation with minimal extra runs, saving time and cost.

During routine operations the operator had cut and pulled old production tubing and the work-over team was then however unable to drift the production casing while attempting a clean-up run.

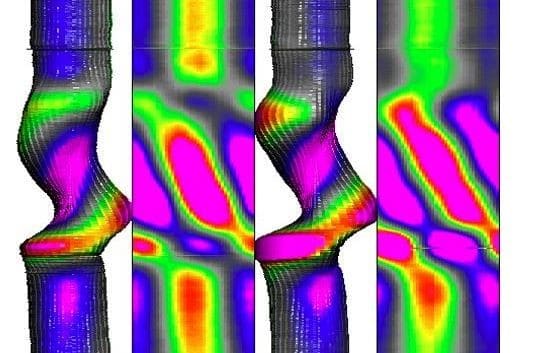

To diagnose the problem a 40-arm extended reach multifinger caliper was run and ANSA was on standby to deliver a comprehensive analysis of the data. Within three hours of data acquisition, the ANSA team produced a report that identified severe localized buckling towards surface in the

production casing.

This field is often monitored for pipe deformation caused by sub-surface subsidence, and this well had no prior issues, until now.

The operator was able to confirm one other documented subsidence case in the area and was able to create a remediation plan moving forward to successfully complete operations with minimal downtime and cost.

Tension was released on the casing at surface to minimize the buckling and a second caliper was logged. ANSA compared the two runs and determined there was little improvement after remediation.

Follow-up drift runs were equally unsuccessful. It was then determined the production casing was in such poor condition it was decided to pull and recomplete.

Prior to recompleting, a third caliper was logged to determine the condition of the surface casing to look for additional signs of buckling.

ANSA determined that severe buckling was present in the same location as prior completion string. The customer was able to mill the affected area, and complete the job successfully with minimal extra runs.

For quick accurate answers and to learn more about ANSA’s data analytics capabilities visit https://ansa-data.com

ANSA Customer Support

+44 (0) 1224 336624 sales@ansa-data.com

Aberdeen Data Hub

Viking House, 1 Claymore Avenue, Aberdeen Energy Park AB23 8GW. UK

Houston Data Hub

Suite 330 9940 W. Sam Houston Parkway S. Houston, Texas 77099. USA